I wanted to write a DIY fix for this issue. It sounds somewhat common, and when I had this happen, the only solution was the replace the switch (still the best solution, but I’d like to show what I did to solve it, before a new switch arrived).

Very short back story. This happened on my wife’s ST on a Thursday night. The dealership (25 miles away) had my 2022 Raptor in for service, so, with this issue, if we needed to drive any distance, it would cause a problem. On top of that, we have an 8 week old baby. So, I felt at a disadvantage with only having one car, and that one car having a busted window. My truck was going to be ready the next day, and I would pick up a new switch at the dealer. I bagged and taped the window on the ST, confirmed the dealer had the driver switch in stock, and I’d handle it tomorrow. Friday comes and goes, truck isn't ready. So, Saturday morning I call and find out this new dealership closes their service,

and their parts department fully on the weekends (That's new for me. Parts and Service were both always open on Saturdays at my old dealership). So, we are now stuck until Monday with no truck, and an ST with a window down for 2+ more days.

I read the others saying the problem was linked to the driver door switch module. I had relay clicking when going up/down on any window switch other than DOWN on the rear passenger window. So, figured it was the main switch in the drivers door like every said, and not the door switch itself.

The driver door switches pop off with just a couple clips. Tried cleaning out the connectors. No joy.

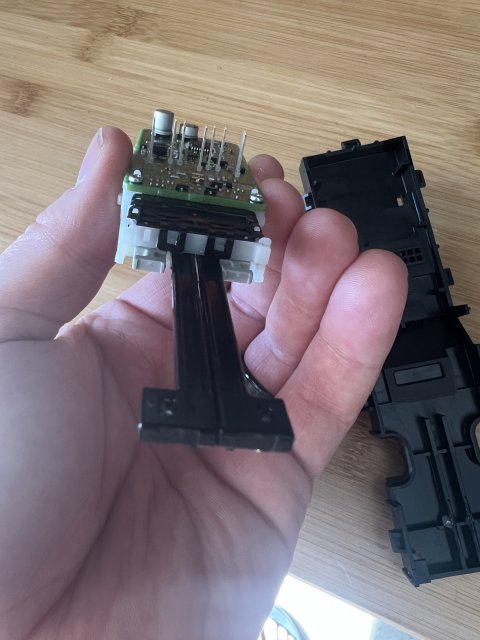

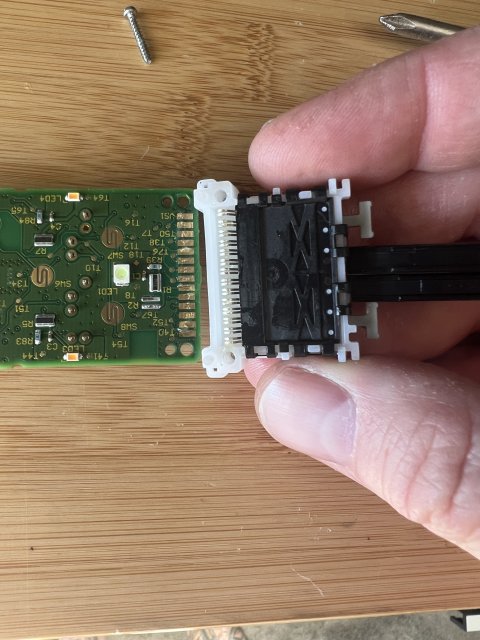

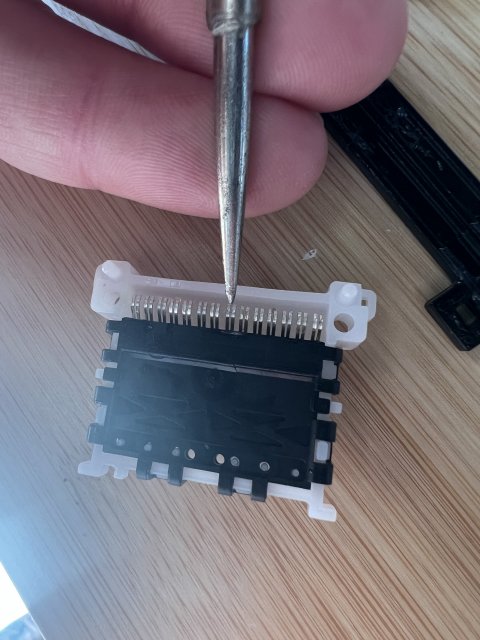

Popped apart the switch back to see how it worked. I used a series of flathead screwdrivers to pry and hold each clip to get the rear cover off that had the plug connector on it.

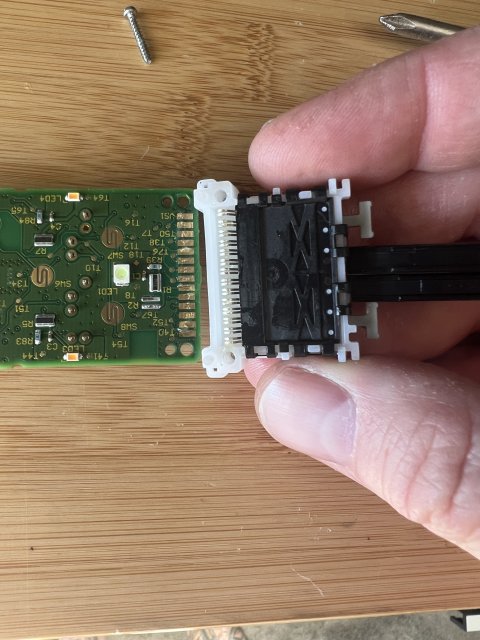

The rear window switches are controlled by longer black arms, and the front switches by the gray shorter arms. When you toggle a switch, it pulls those arms in, then releases them. This is the mechanical operation of the switches. The next part goes over how the switch turns those mechanical operations into electrical ones.

I took apart the white box (w/ black bottom) that was housing the mechanical mechanism that was being actuated by the switch movement. It's held onto the circuit boar by 2 Phillips screws.

Exploded view once you open the box:

The long black arms were rolling over small little white plastic levers (Seen above, they look like the mechanism behind piano keys) that had a small amount of tension on them. When you move the window "open" or "closed" via a switch, it puts the white plastic piano looking levers into a detent on whichever arm is being moved by the switch (long black, short gray, etc), which then makes the white plastic levers push down on a metal connector that sits below it. That movement makes it touch, or not touch, the circuit board contacts, telling it to "open" or "close" the window. That’s the basic function. (I have a small amount of circuitry board knowledge, but a large amount of mechanical knowledge. So, sorry if that was confusing).

I found the white plastic lever, and accompanying metal connector that operates the rear passenger window. Pointing here (if your bad window is a different window, just follow which levers are being pushed down when you rock back and fourth the appropriate black or gray arm:

The associated metal connector that the lever pushes down:

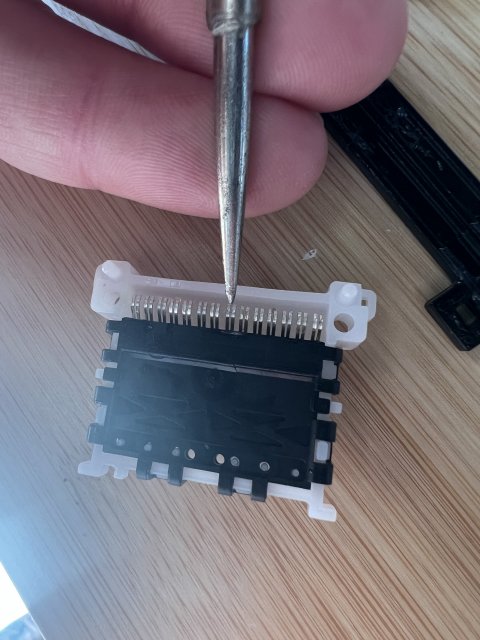

The white lever for the rear passenger window was clearly pushed over to one side, and slightly down:

This meant the metal connector underneath it was in constant contact with the plate on the circuit board. Hence why every other window operation would make a relay noise (being told to open or close) and this one wouldn’t, because it was in constant contact with the circuit board telling it that it's "constantly pressing the window down switch". It even had a little darker mark on the circuit board contact, and the bottom side of the metal connector was brown tinged. So, I scraped off any burned looking material gently on both the metal connector, and circuit board, spread the di-electric grease evenly along the boards, and proceeded to bend back the white lever straight.

But, it had too much tension down still, and wanted to make the connector still be pushed down, even at the standard position. So, I propped it up, and clipped off about 1-2mm of the white lever. This gave some breathing room to the metal connector underneath it. You can see that here. The farthest right white lever that's propped up is cut shorter:

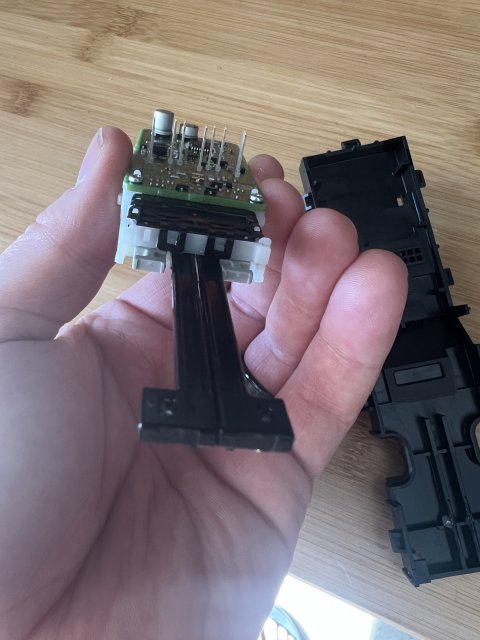

Once I did that, I put the box back together, slid the arms into their places, and screwed it back onto the circuit board.

I checked operation a few times before reinstalling it all back together w/ the actual switch. But we were good to go! The passenger rear window rolls up and down just fine!

This isn’t the end all solution. But, got the window working again, and I have a switch on the way and didn’t have to go to the dealership. And they were closed for two more days anyway. All in all, with the diagnosing, this took about an hour. Hopefully if you see this and have a window that just stopped working one day (likely in the down position) and hear relay clicking everywhere, you can use this to help solve it and get the window back up. I only had to cut the white lever because it kept wanting to contact the metal connectors. It was just too far depressed even after I tried to gently bend it back. So, exercise some caution when bending those white looking levers, and also if you have to cut the one that's an issue.

I hope this helps anyone else stuck in this situation! Just take your time and it’s all pretty easy!

1