Looking for some guidance on a leak after installing my Nostrum fuel pump. It is the low pressure side fitting and it is only a drip or two but still a leak. I tried to remove the line and reseat it but can’t get my removal tool to fit as there is not enough space between the fitting and the pump housing? Anyone else run in to this? Thoughts on how to fix it? Any guidance is greatly appreciated!

-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Explorer ST Forum and Explorer ST community dedicated to Explorer ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Explorer ST Forum today!

Low Pressure Gas Line Leaking After HPFP Install?

- Thread starter -REDRUM-

- Start date

Thread Starter

#3

Thread Starter

#3

Attached is a pic... the car is back together so it is tough to get a picture of the actual leak. It is dripping from the Low Pressure fitting down the back of the Fuel Pump. Again, not a lot, but enough that you get gas on your fingers if you rub them back there...

Attachments

-

1.3 MB Views: 46

Ok! Let's tackle this!

So in my experience, while removing the quick disconnect on the low pressure side, I ever so slightly nicked the o-ring and it produced a leak. I replaced both o-rings but I just could not get it to stop leaking. Not much, but enough that I could smell it in the car, and if I touched it, my finger would be wet.

Ultimately what I decided to do was remove the old hard line and make my own custom fuel line with quick disconnect fittings that do not require the removal tool.

I used AN6, PTFE line and fittings https://www.amazon.com/gp/product/B07JF93GG6/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 Watch a video on YouTube how to terminate the ends, it isn't too bad but did take me two tries to get it right. I'm guessing if I had a bench vise it would have been slightly easier than doing it in my hands.

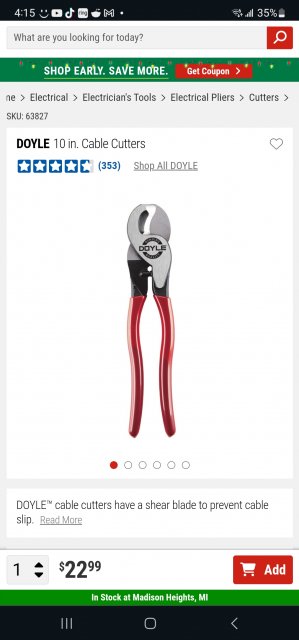

See attached photos, cutter is important for clean cuts on the PTFE line, don't use a grinder or crappy cutters, you need a very straight and clean cut.

Side note: I did end up zip tying the line at the bend to a random hose, not tight or anything but it was vibrating enough you could hear it in the car rubbing the plastic on the passenger side of the engine bay. Zip tied it just enough to pull it away from the side wall and that problem went away.

So in my experience, while removing the quick disconnect on the low pressure side, I ever so slightly nicked the o-ring and it produced a leak. I replaced both o-rings but I just could not get it to stop leaking. Not much, but enough that I could smell it in the car, and if I touched it, my finger would be wet.

Ultimately what I decided to do was remove the old hard line and make my own custom fuel line with quick disconnect fittings that do not require the removal tool.

I used AN6, PTFE line and fittings https://www.amazon.com/gp/product/B07JF93GG6/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 Watch a video on YouTube how to terminate the ends, it isn't too bad but did take me two tries to get it right. I'm guessing if I had a bench vise it would have been slightly easier than doing it in my hands.

See attached photos, cutter is important for clean cuts on the PTFE line, don't use a grinder or crappy cutters, you need a very straight and clean cut.

Side note: I did end up zip tying the line at the bend to a random hose, not tight or anything but it was vibrating enough you could hear it in the car rubbing the plastic on the passenger side of the engine bay. Zip tied it just enough to pull it away from the side wall and that problem went away.

Attachments

-

353.7 KB Views: 36

-

2.3 MB Views: 34

-

2.5 MB Views: 34

-

1

- Show All

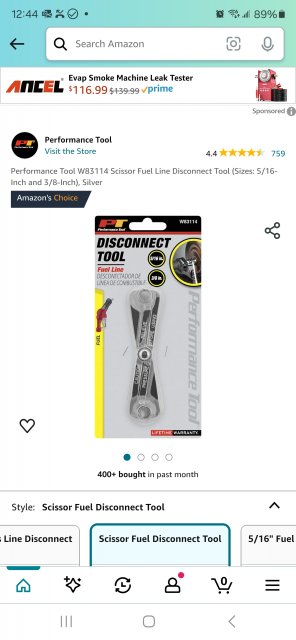

So what I did was I took these (see photo) and I slowly grinded away at the tips. They need to be a few mm smaller to fit in the bell of the oem fuel line to remove it. I can measure them with my calipers tonight when I get home if you want to know. Essentially each arm is slightly different in length. I was able to slide one side in at a time then use both hands to simultaneously push the fuel line down and the disconnect tool up. I also made the call to swap out the line for the AN6 disconnects because they are sooooo easy to get on and off comparatively and don't have to worry about the o ring situation.

Attachments

-

729 KB Views: 30

Best of luck and I hope this helps.

-

3

- Show All

I did forget I also ordered these:

https://www.amazon.com/gp/product/B001P2CKVY/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

https://www.amazon.com/gp/product/B0C6TJMJSR/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 EDIT (Will not need these, see next post).

I did this before when I installed my e85 sensor and totally forgot you will need the disconnects to make this custom fuel line work.

https://www.amazon.com/gp/product/B001P2CKVY/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

https://www.amazon.com/gp/product/B0C6TJMJSR/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 EDIT (Will not need these, see next post).

I did this before when I installed my e85 sensor and totally forgot you will need the disconnects to make this custom fuel line work.

Last edited:

I only bought the male push on adapter because I broke a vacuum line. I threaded the plastic with a tap and dye kit, then I screwed one of those male adapters in with epoxy. The yellow arrows shows where it broke and the female vacuum line that clipped on. Ford wanted like 300 dollars for the plastic tube, it goes from the turbo to the airbox. So this was much more economical.

Sorry to keep replying to myself. I did the sensor so long ago I forgot the orientation of the lines. So the original fuel line I removed was female on the pump side and male on the other. So my original advice won't work. You will need to find a way to terminate your fuel line to be male on one side (the link I sent that says you won't need this should work). Again, sorry I meant to be helpful and not so forgetful.

Obviously if you add the fuel-it ethanol sensor then you can go female to female like I did. Just had a memory lapse. Hoping pictures will clarify.

Obviously if you add the fuel-it ethanol sensor then you can go female to female like I did. Just had a memory lapse. Hoping pictures will clarify.

Attachments

-

1.6 MB Views: 20

-

2.3 MB Views: 20

Explorer ST Posts

-

Welcome to the Explorer ST Forum, please post an introduction

- Latest: Nascarbilly

-

-

-

-

CvFab Intercooler / FenFab HKS Charge Pipe Kit Installed

- Latest: BrooseDaMoose

-

-

-

-