Turbo lag. Especially on a 4700+ lb vehicle is to be avoided at all costs. This is especially true from a marketing perspective- after all if you're doing engine downsizing, that last thing you want is your customers not to feel an immediate "kick in the pants" off idle. Especially since the platform in question has been programmed to spend most of it's life at 1500 rpm!. As an aside, if you've ever driven a naturally aspirated big-cammed car, or even say an S2000, you understand that "lag" doesn't just apply to turbochargers.

So how does the ST having twin turbos address this? To achieve maximum compressor "spool" (acceleration), you have four factors: First, you use small turbines. Sure, they will limit performance up high, but due to a small A/R they will accelerate more quickly due to increasing the velocity of the exhaust through the turbine. Second, you move the turbine as close to the flow source as possible to minimize heat (energy) loss. That's why you see the turbines attached to the head. Third, that minimal distance from the exhaust port to the collector (turbine entrance) means that at lower RPMs, a pressure wave is reflected back towards the still open exhaust valve, helping to evacuate the cylinder (if you don't understand this, ask questions!). Fourth, and most importantly, you harness a "pulse" driver. What many may not know is that a 3 cylinder is especially well suited to turbos. That's because you have an engine firing every 240 degrees of crankshaft rotation. What else is happening at 240 degrees of crankshaft rotation? Cam timing. Meaning that only one exhaust valve is open at a time. These "hammer" strikes from the exhaust pressure waves and lack of interference (other open valves, competing flow) help to motivate the turbine faster at lower RPMs. At higher RPMs, it doesn't make any difference.

Now, none of this means that two turbos aren't adequate, but given my penchant for "bang for the buck", the available bolt-on hybrid turbos with the same frame size aren't optimal. Sure, you could go for two "larger" turbos, but that means for any applicable twin setup twice the price and twice the fabrication.

Let's assume you're curious, what's ST capable of?

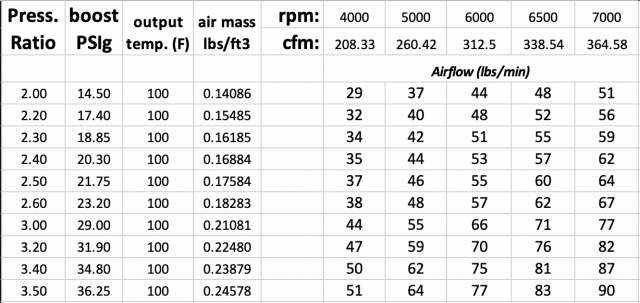

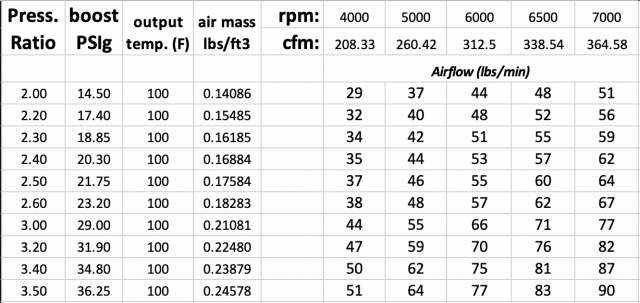

Let's take a look at a spreadsheet I developed with thoughts to a replacement single turbo which will give us the numbers we need to look at compressor charts and to get some concrete math as to what might be expected horsepower-wise from the engine:.

The leftmost column is Pressure Ratio or P/R on your compressor map. It represents the difference between the ambient air pressure and the compressor output pressure and is the "Y" axis on a compressor map.

The second column is the resulting "boost" pressure measured in PSI (gauge) and assumes 1 Bar or 14.5 psi to be ambient pressure. Temp is the output from the intercooler- I've held this the same although it can be adjusted to represent intercooler efficiency and compressor efficiency. If you're curious about this, ask- I'll address compressor efficiency vs temperature rise with equation if anyone cares.

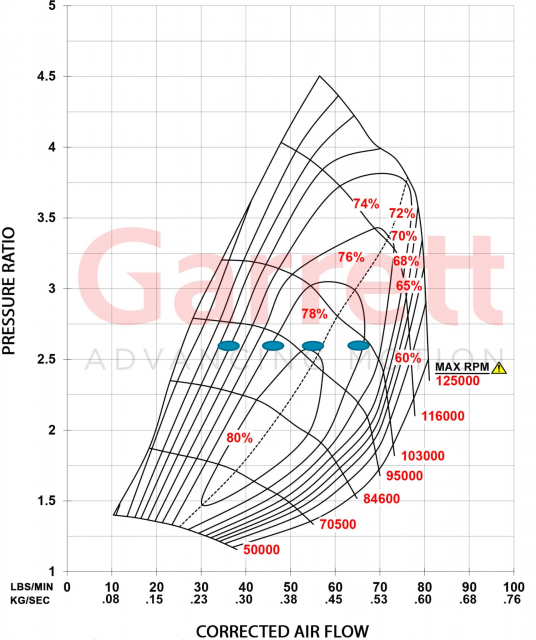

Air mass is the resulting lbs per cubic foot of air. The RPM and CFM column represent the cubic feet of air the engine can injest at those RPM points at 100% VE (curious as to why? Ask questions). The Airflow table then measures the actual mass airflow in lbs/minute for each row. For example, the first row shows at a 2.00 P/R or 14.5 psi of "boost", the airmass at the various RPM points will be 29, 37...48, 51 lbs/min. Each of those mass flow numbers represents the "X" axis on a compressor map. Now as a rule of thumb, we can multiply each of these numbers by 10 to result in HP on gasoline. So, we could expect approximately 290 HP at 4000 RPM, up to 510 HP at 7000 rpm.

4