-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Explorer ST Forum and Explorer ST community dedicated to Explorer ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Explorer ST Forum today!

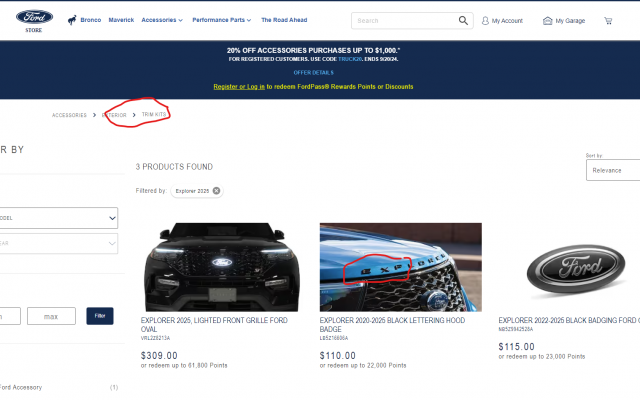

Laughing at alignment on Ford's site

- Thread starter sharpcode

- Start date

- Messages

- 2,773

- Reactions

- 1,238

- Points

- 252

- Location

- Nevada

- Vehicle

- '20 Raptor, '22 Explorer ST, '14 GT500, '03 F150

I may be wrong, but aren't both the alignment of the lettering on the badge (especially the "X") and the breadcrumbs (especially the "TRIM KITS") off on alignment on the official accessory site? Gave me a laugh.

Well.. I know a lot about this issue - I was a Sr. Program Manager at the company that manufactures these and most other Ford emblems and badges (plus lots for all other domestic & foreign automakers).

The lettering is incased in a black foam liner (carrier) that spaces and positions each letter accordingly. There is clear film over the top visual side of the letters in the foam liner and a white backing liner on the back sticky side of the letters.

The top clear film is sticky on the side that is up against the letters in the black foam liner. This is so that when the white liner is remover for application at the assembly plant, the letters stay in place and in position in the foam liner because they stick to the clear liner. Here is where the issue happens, sometimes when the entire carrier is put into the wet-out machine at the assembly plant and then the white liner is removed, a letter or two, etc. can stick to the white liner instead of staying stuck to the sticky clear liner. Assembly line workers pull off the letters that stuck to the white liner and shove them back into the off foam carrier - If this is not done carefully and miticulously, you will end up with letters crooked on the hood.

It has always been a challenge to find materails that aren't too sticky or not sticky enough to accomplish the assembly task with the clear and white liner material.

The lettering is incased in a black foam liner (carrier) that spaces and positions each letter accordingly. There is clear film over the top visual side of the letters in the foam liner and a white backing liner on the back sticky side of the letters.

The top clear film is sticky on the side that is up against the letters in the black foam liner. This is so that when the white liner is remover for application at the assembly plant, the letters stay in place and in position in the foam liner because they stick to the clear liner. Here is where the issue happens, sometimes when the entire carrier is put into the wet-out machine at the assembly plant and then the white liner is removed, a letter or two, etc. can stick to the white liner instead of staying stuck to the sticky clear liner. Assembly line workers pull off the letters that stuck to the white liner and shove them back into the off foam carrier - If this is not done carefully and miticulously, you will end up with letters crooked on the hood.

It has always been a challenge to find materails that aren't too sticky or not sticky enough to accomplish the assembly task with the clear and white liner material.

Last edited:

-

3

- Show All

Thread Starter

#4

Well.. I know a lot about this issue - I was a Program Manager at the company that manufactures these and most other Ford emblems and badges (plus lots for all other domestic & foreign automakers).

Assembly line workers pull off the letters that stuck to the white liner and shove them back into the off foam carrier - If this is not done carefully and miticulously, you will end up with letters crooked on the hood.

It has always been a challenge to find materails that aren't too sticky or not sticky enough to accomplish the assembly task with the clear and white liner material.

View attachment 25284

Assembly line workers pull off the letters that stuck to the white liner and shove them back into the off foam carrier - If this is not done carefully and miticulously, you will end up with letters crooked on the hood.

It has always been a challenge to find materails that aren't too sticky or not sticky enough to accomplish the assembly task with the clear and white liner material.

View attachment 25284

-

1

- Show All

- Messages

- 1,629

- Reactions

- 1,064

- Points

- 162

- Location

- East Freetown, MA

- Vehicle

- 2020 Explorer ST, Silver Spruce Metalic

That's super interesting! Thanks for the background on this. I bet humidity changes day-to-day could play a part in this too. If it's not obvious when you get it, and you only realize after you've installed it, it would be a bit of a chore to fix. It's odd that the photo advertising the product suffers from this issue though! Goes to show that the original factory likely has better installation methods than you would have at home.

-

2

- Show All

Given the fact it's an assembly line and things are moving quick, I'd imagine it's quite common for this to happen. I doubt they have time to use a straight edge to line it up. Interesting information though @Caster!

Last edited:

-

1

- Show All

Thread Starter

#8

The factory has a wet-out machine custom built for each and every emblem on a vehicle. Wet-out (which is kind of a strange term) means to fully push each emblem or logo that is attached with double sided tape, 100% against the surface it is to adhere to in order to achieve 100% tape to surface adhesion. Anyway, the wet out machine fixture locates these particular letters that are in the black foam carrier via dowel pins that poke through the (5) round locating holes you see in the picture. The wet-out machine places the letters on the vehicle in whatever orientation the letters are in within the carrier. The wet-out machine only centers the letters (up, down, right & left) on the hood and pushes them onto the hood surface. It has nearly nothing to do with the specific orientation or spacing of each of the letters. **If any letter is crooked in the carrier for whatever reason from the manufacturer, they will of course end up being installed on the hood crooked as well. A crooked letter is not always the fault of a line worker.

-

3

- Show All